• Types of industrial electrical systems, such as AC and DC, are essential for manufacturing facilities.

• Advantages include cost-efficiency, reliability, and reduced energy consumption. Reduce costs by taking advantage of energy efficiency initiatives.

• Safety considerations, such as regular inspections and the installation of proper safety equipment, must be taken into account.

• Employee training on electrical safety practices is necessary to ensure everyone understands the risks and how to identify any issues.

• Regular maintenance of industrial electrical systems is critical for keeping them running safely and reliably over time.

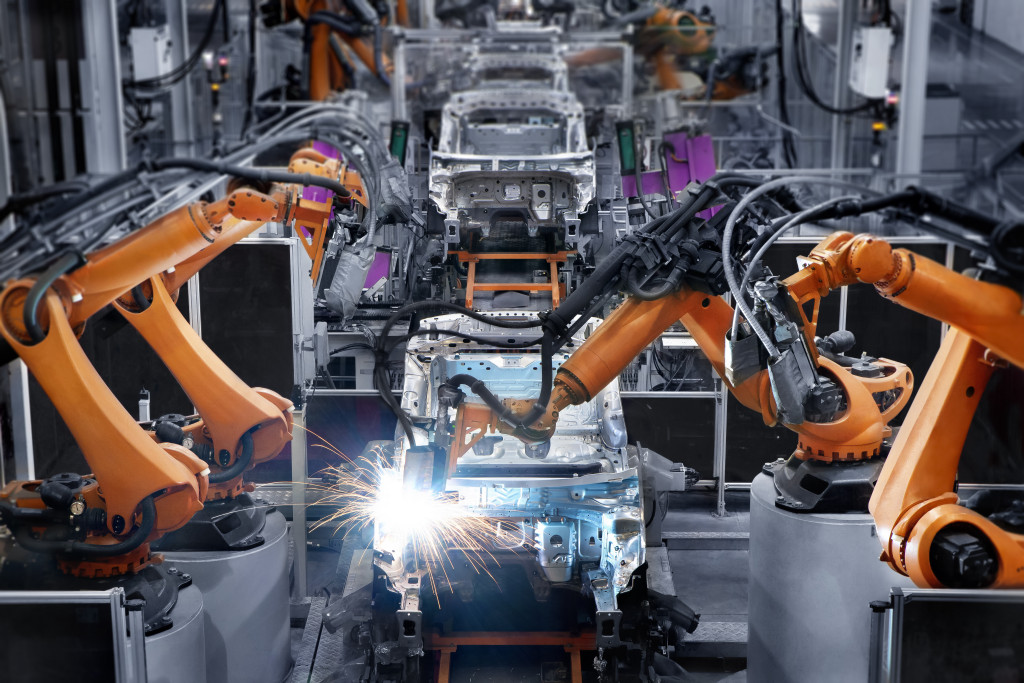

In the manufacturing industry, industrial electrical systems are essential for success. With the right system in place, you can power your machines and increase production while making sure that your facility is safe and compliant with local regulations. Read on to learn more about the things you should know about industrial electrical systems in the manufacturing industry.

Types of Industrial Electrical Systems

Industrial electrical systems come in many shapes and sizes, but there are generally two main types: AC (alternating current) and DC (direct current). Alternating current is the most common type of power used in commercial buildings, whereas the direct current is typically used for smaller applications like computers or motors. It’s essential to understand which kind of system you need for your manufacturing facility before investing in any equipment or installation services.

Advantages of Industrial Electrical Systems

Industrial electrical systems offer a variety of advantages over traditional power sources such as generators or transformers. Not only do they provide a reliable source of energy, but they also reduce costs by eliminating the need for additional infrastructure and personnel to manage it.

Additionally, these systems are designed to be efficient, so they use less energy overall than traditional sources. This means you can reduce your energy consumption while still powering all your equipment without worrying about running out of power during peak production times.

Safety Considerations

Safety is always a priority when dealing with electricity. Industrial electrical systems must be properly installed and maintained to ensure all safety measures are followed. This includes the following things:

Ensure all wiring is up-to-date

Ensuring that all wiring is up-to-date and up to code is essential when dealing with industrial electrical systems. Qualified personnel should conduct inspections regularly to ensure that wiring is safe and compliant with local regulations.

Install proper safety equipment

Safety equipment such as circuit breakers, fuses, and protective relays should be installed to protect your facility from power surges and other unexpected events.

Ensure sensitive electronic components are properly grounded

When dealing with sensitive electronic components, it’s essential to properly ground them to prevent damage. This will also help protect your facility from potential electric shocks or fires.

Train your personnel on electrical safety practices

Your personnel should be well-trained in the basics of electrical safety and be able to identify potential risks. This way, they can take the appropriate steps to ensure everyone stays safe while dealing with industrial electrical systems.

By ensuring all safety considerations are taken care of, you can ensure that your industrial electrical system is reliable and safe.

Energy Efficiency Initiatives

One way to make sure you get the most out of your industrial electrical system is by taking advantage of energy efficiency initiatives available through utility companies or government programs. These programs often provide incentives for businesses that upgrade their existing systems with more efficient technology or take steps to reduce their overall energy consumption by using smart technologies such as motion-activated lighting or automated shutoff switches when equipment isn’t being used for extended periods.

Maintenance Requirements

Keeping up with regular maintenance of industrial electrical systems is essential for ensuring safety and reliability over time. This includes inspecting and testing wiring on a regular basis, replacing worn parts as needed, ensuring proper grounding techniques are utilized throughout the facility, and checking circuit breakers occasionally for signs of wear or malfunctioning components that could lead to an unexpected outage during peak production hours if left unchecked too long.

Proper Implementation

Installing and maintaining an industrial electrical system is no simple task. To ensure that your system is correctly implemented, consulting with a qualified electrician with experience working in the manufacturing industry is essential. This will help you identify any potential issues before they become significant problems, so you can rest easy knowing that your facility operates under the safest, most reliable power source available.

Or, better yet, you should pursue a career in industrial electrical work yourself to get a better understanding of the industry from the ground up. With proper training and experience, you’ll be able to enhance your skills in this field and ensure that your facility has all the power it needs to keep production running smoothly.

Industrial electrical systems are essential for the success of any manufacturing facility. By following the tips discussed in this blog, you can rest assured that your factory has all the power it needs to keep production running smoothly while staying safe and compliant with local regulations.